Why Snap Action Micro Switches Are a Go-To Choice for Home Appliances and Safety Systems

1. Introduction

In modern home appliances and safety systems, reliability, precision, and compact design are critical. Snap Action Micro Switches have become a trusted component for ensuring stable performance in demanding environments.

2. Definition and Working Principle

A Snap Action Micro Switch is a precision electromechanical device that rapidly changes contact state when a specific force threshold is reached. This “snap” mechanism minimizes contact bounce, improves repeatability, and extends service life — making it well-suited for compact, high-reliability applications. It operates via a spring-loaded mechanism that, upon actuation, quickly flips the contacts from open to closed (or vice versa), helping ensure stable switching with minimal arcing and wear.

3. Trigger Mechanism and Response Time Advantages

The unique trigger mechanism of snap action micro switches provides very fast switching response times — often in the millisecond range — which helps reduce signal noise and prevent contact chatter. This rapid action also supports longer service life by reducing arcing damage. The mechanical design supports consistent actuation force and repeatability across millions of mechanical cycles, making it suitable for frequent switching applications.

4. Contact Materials and Performance

Contact composition plays a critical role in durability and conductivity. Silver alloy is widely used for its balance between cost and electrical performance. Gold-plated contacts are preferred in low-current, high-precision signal applications due to their resistance to oxidation. Selecting the right contact material for the intended load and environment is essential to achieving long service life and stable contact resistance.

5. Core Advantages of Snap Action Micro Switches

Snap Action Micro Switches offer several advantages that make them a practical choice in home appliances and safety systems:

·High Reliability – The snap mechanism helps ensure consistent and repeatable contact operation, minimizing bounce and electrical noise.

·Long Lifespan – Under proper operating conditions, these switches can achieve millions of mechanical cycles, with electrical life depending on the load and model.

·Compact Size – Small form factors allow integration into space-constrained designs without sacrificing performance.

·Cost-Effectiveness – Compared with larger electromechanical switches or certain solid-state alternatives, snap action micro switches provide a balanced trade-off between cost and functionality.

·Fast Response Time – Rapid switching improves system responsiveness, which is especially valuable for safety-critical applications.

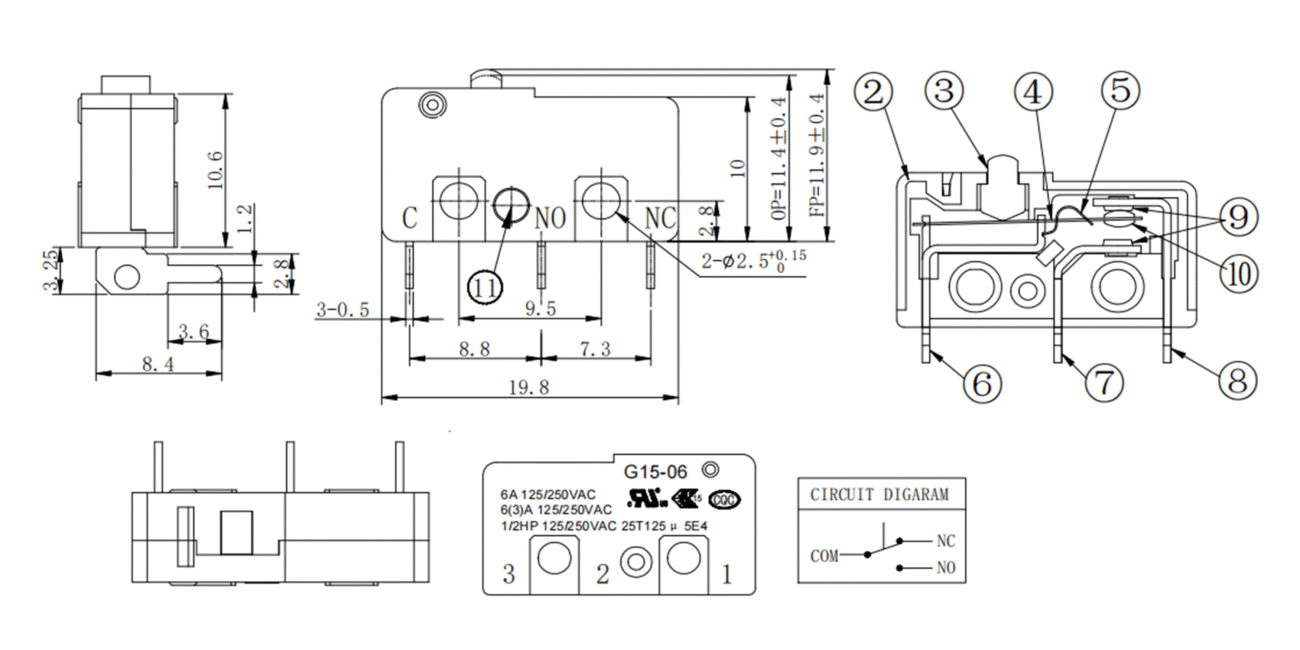

6. Actuation Parameters Explained

Key mechanical parameters include:

·Operating Force (OF) – Force required to actuate the switch.

·Release Force (RF) – Force at which contacts return to their original position.

·Overtravel (OT) – Distance the actuator can move beyond the operating point.

·Differential Travel (DT) – Movement between actuation and release points.

Understanding these parameters ensures mechanical compatibility with the host device.

7. Electrical Specifications

Electrical ratings vary between models. Typical values for certain models on swiclick.com include:

| Parameter | Description | Typical Value/Range* | Notes |

| Rated Current/Voltage | Maximum allowable operating current and voltage | e.g., 1A 125VAC or 10A 250VAC | Model-dependent |

| Insulation Resistance | Resistance between contacts and housing | ≥100 MΩ (500V DC) | Ensures insulation integrity |

| Contact Resistance | Resistance when contacts are closed | ≤50 mΩ | Affects conductivity |

| Electrical Life | Number of switching cycles under rated load | ≥100,000 cycles (varies) | Load- and model-specific |

| Dielectric Strength | Voltage withstand between contacts and housing | 1000VAC for 1 minute | Verifies insulation strength |

*Values depend on the specific switch model; refer to product datasheets for exact ratings.

8. Integration and Connection Methods

Effective integration depends on selecting the right connection and mounting methods. Common terminal types include PCB solder pins for compact circuit board assembly, quick-connect terminals for easy installation and replacement, and wire leads for flexible wiring in confined spaces. Mounting options such as panel mount, bracket mount, or direct PCB mount can influence mechanical stability and serviceability.

9. Reliability and Endurance Testing

High-quality micro switches undergo:

·Mechanical life testing – Millions of cycles without load.

· Electrical life testing – Under specified loads.

·Environmental testing – High temperature, humidity, and vibration resistance.

These tests verify performance consistency over the product’s service life.

10. Typical Applications

Snap Action Micro Switches are widely used in home appliances and safety systems. For example:

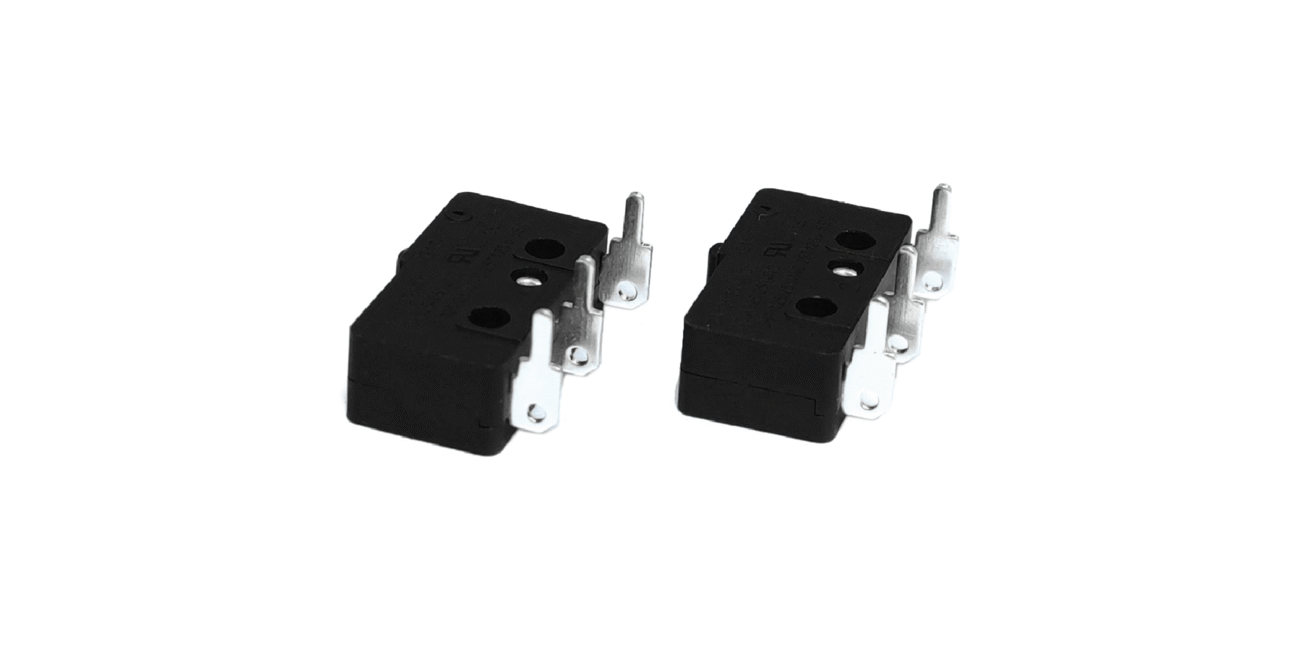

– 1A 125VAC Limit Mouse Micro Switch – Features stable contact resistance (≤50 mΩ) and a mechanical life exceeding 500,000 cycles, making it suitable for precision control in compact devices.

– Snap Action Solder Pin SPDT Micro Limit Switch – Offers a metal housing, solder pin terminals, and electrical ratings up to 10A at 250VAC. Its snap action mechanism ensures quick and reliable switching, which is beneficial for safety-critical devices.

11. Conclusion and Selection Advice

Snap Action Micro Switches provide dependable, responsive, and space-efficient switching solutions for home appliances and safety systems. By selecting models with the right electrical ratings, mechanical parameters, and contact materials for the application, manufacturers can improve safety, reliability, and customer satisfaction — all while ensuring that specifications align with real-world product capabilities.