How Are DPDT Slide Switches Used in Industrial and Consumer Electronics?

1. Introduction

In the fast-paced realm of industrial automation and precision electronics, every component must earn its place on the circuit board. The DPDT Slide Switch, valued for its reliable dual-pole, dual-throw functionality, plays a critical role in many electronic applications. Whether tucked inside a control panel or integrated into test gear, it enables quick, reliable state transitions with minimal fuss. This article dives into how this robust switch elevates both the usability and dependability of your equipment.

2. What Is a DPDT Slide Switch?

A DPDT Slide Switch integrates two independent switches into a single sliding mechanism, allowing control of two separate circuits, each capable of switching between two outputs. Its common ON–ON or ON–OFF–ON wiring makes it ideal for motor direction changes, switching between redundant power sources, or toggling between operational modes—all with a firm, tactile slide.

3. Why Slide Switches Outperform in Challenging Environments

Unlike rocker or toggle switches, slide variants excel in:

·Dense PCBs: Low-profile and space-efficient for compact panels.

·Vibration resilience: Secure mechanical detents prevent accidental toggles.

·Dust control: Flush surfaces limit exposure in industrial settings.

Essentially, they deliver robust performance where precision matters most.

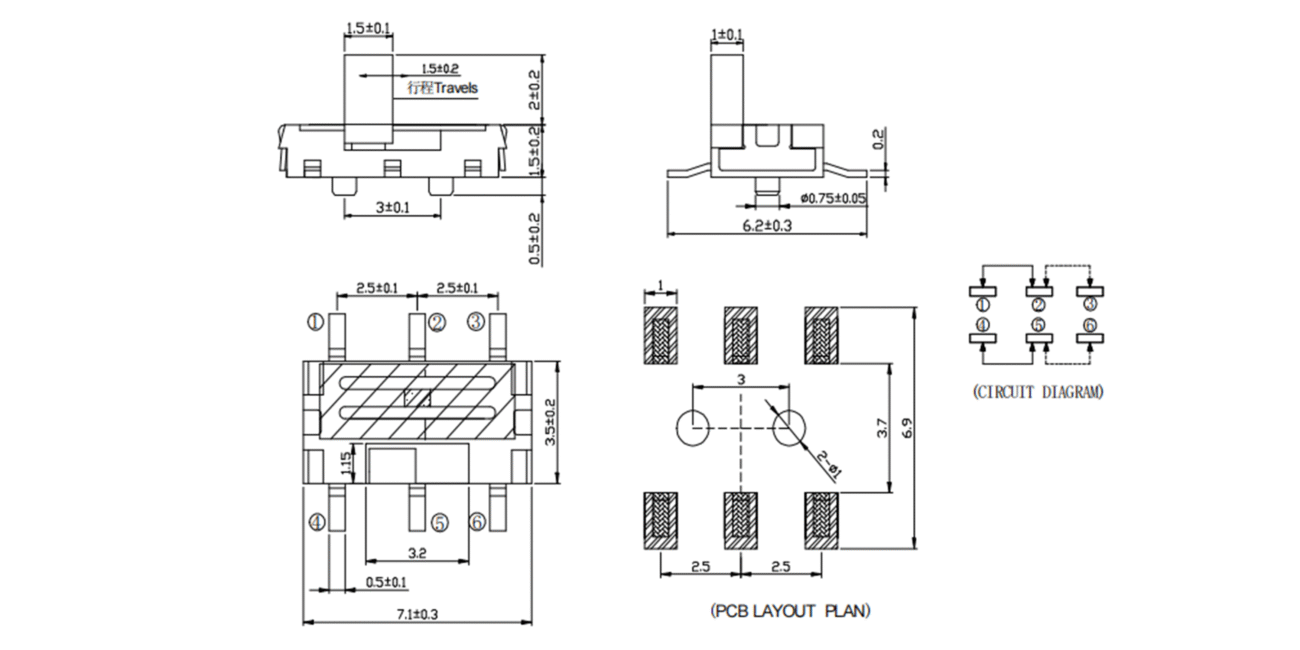

4. Inside & Wiring Configurations

Internally, a sliding plunger shifts conductive paths to create different circuit states.

– ON–ON: Direct swap between two circuits.

– ON–OFF–ON: Safe middle position for isolation.

Whether reversing a motor’s spin or alternating between main and backup lines, these configurations provide clean transitions.

5. Key Specs & Selection Guidelines

Choosing the right DPDT switch hinges on matching specs to application demands:

| Parameter | Recommended Specification |

| Voltage / Current | ≥ DC 12 V, 100 mA — as a baseline |

| Contact Resistance | ≤ 100 MΩ for minimal signal degradation |

| Insulation Resistance | ≥ 100 MΩ—vital for safety and signal integrity |

| Mounting Type | SMT preferred for compact layouts |

| Load Capacity | For heavier loads, consider variants rated at DC 50 V, 0.3 A |

6. Quality Assurance and Testing Procedures

Ensuring the reliability of DPDT slide switches starts with thorough quality control during production and before shipment. Common testing methods include:

·Electrical testing: Verifying contact resistance, insulation resistance, and voltage/current ratings to meet specifications.

·Mechanical testing: Assessing switch actuation force, mechanical life cycles, and durability under vibration or shock.

·Environmental testing: Evaluating performance under temperature extremes, humidity, and dust exposure to guarantee field reliability.

7. Advanced Features and Technical Advantages

These DPDT slide switches are engineered for durability, precision, and adaptability across a wide range of applications. Key highlights include:

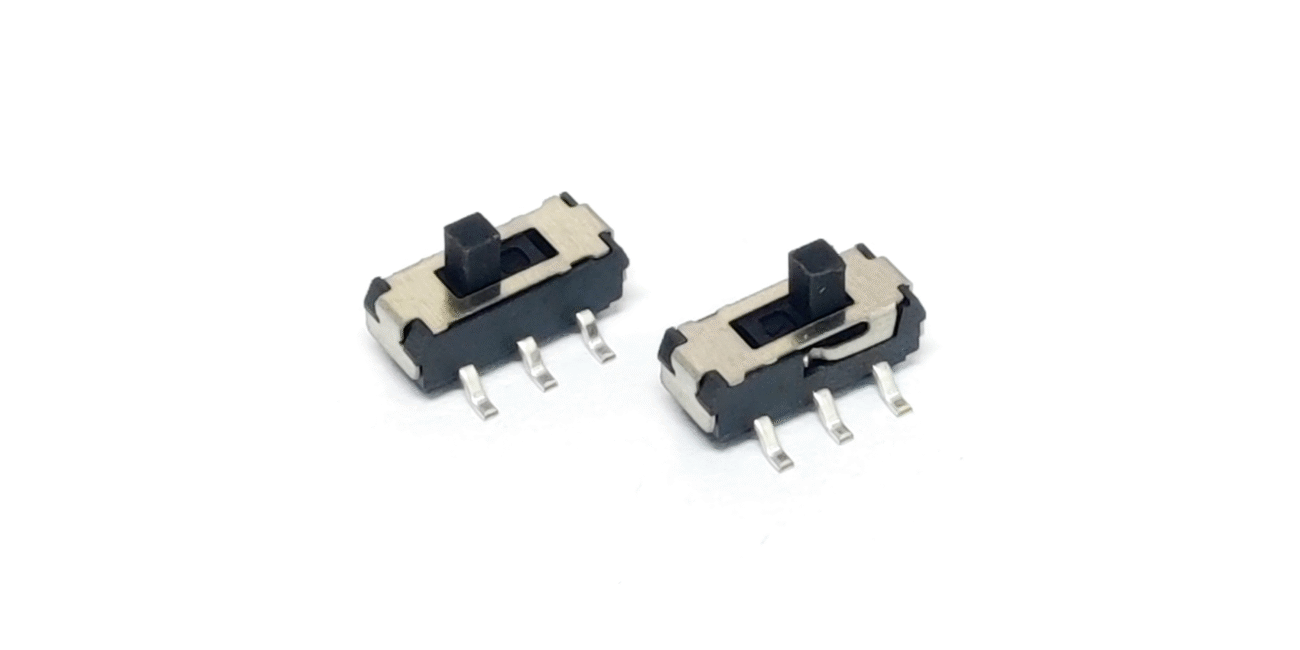

·Compact form factor: Suitable for tight circuit board layouts without sacrificing functionality.

·Reliable contact system: Maintains low contact resistance (≤ 100 MΩ) and stable signal integrity.

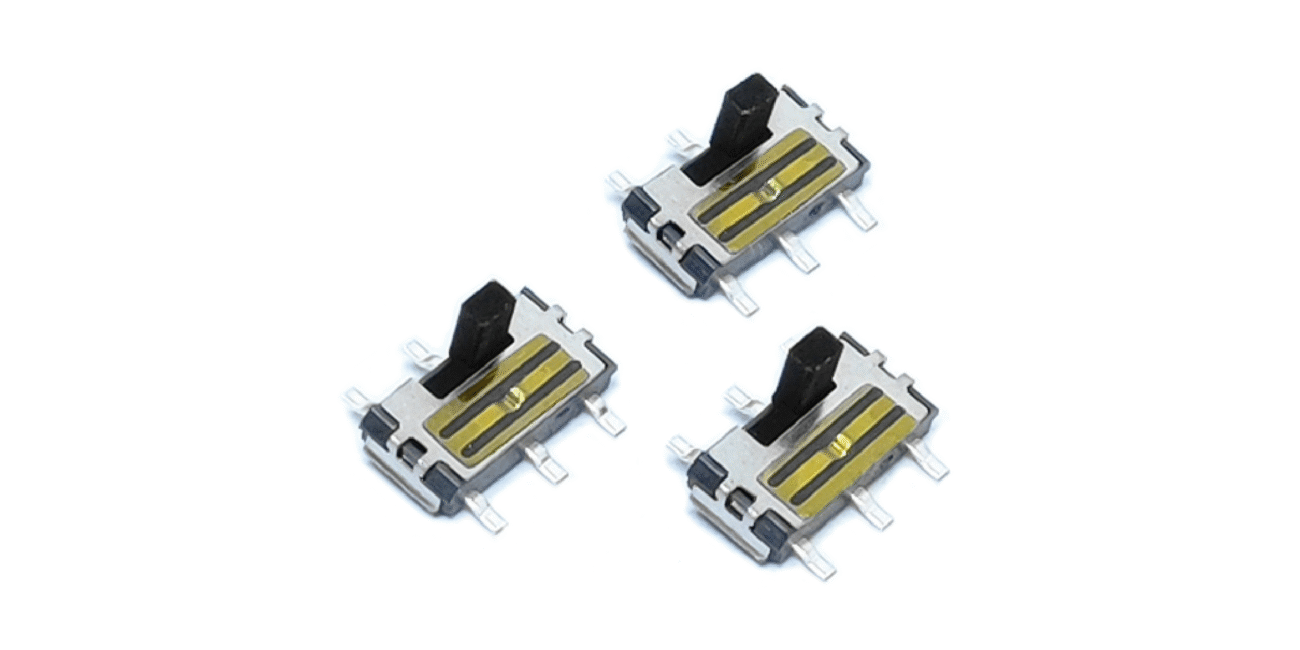

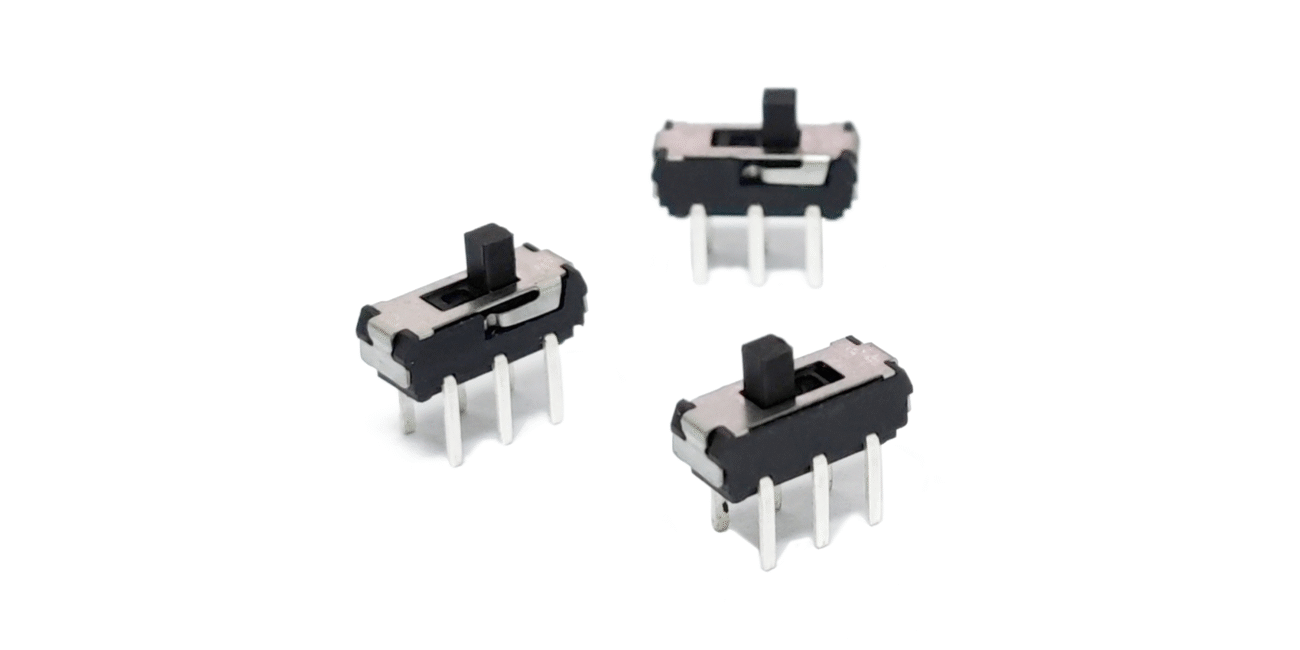

·Multiple mounting options: Available in through-hole, surface-mount (SMT), and miniaturized configurations to meet diverse design needs.

·Wide operating temperature range: Typically –20 ℃ to +70 ℃, making them fit for industrial and consumer electronics environments.

·Robust mechanical lifespan: Rated for tens of thousands of actuations, ensuring long-term reliability.

These features position these DPDT slide switches as excellent choices for precise control in industrial equipment, consumer devices, and testing instruments.

8. FAQ—Precisely Answered

Q: DPDT vs. DPST—what’s the difference?

A: DPDT controls two independent circuits with transition states; DPST only opens/closes two lines simultaneously.

Q: Can a DPDT act as two SPDTs?

A: Yes—if wires remain isolated.

Q: How do I prevent switch arcing on inductive loads?

A: Use snubber circuits or flyback diodes to absorb voltage spikes.

9. Application Case Studies in Industry and Consumer Electronics

In industrial control systems, DPDT slide switches are commonly used to switch between primary and backup power supplies, ensuring continuous operation with minimal downtime. Their reliable dual-circuit control and compact design make them ideal for control panels in manufacturing plants and automation equipment.

In consumer electronics, such switches enable mode selection in handheld diagnostic tools and portable devices. The surface-mount versions fit neatly into small form factors, providing tactile feedback that enhances user experience while maintaining durability through frequent use.

For designers working on dense PCB layouts, miniature DPDT slide switches offer precise control with minimal space requirements. This feature is particularly valuable in advanced testing equipment and compact electronic modules, where reliability and efficient assembly processes are critical.

These examples highlight how DPDT slide switches facilitate versatile, dependable solutions across various sectors without compromising on size or performance.

10. Conclusion

In both industrial automation and consumer product engineering, the DPDT Slide Switchr delivers unmatched value: dual‑circuit flexibility, tactile reliability, and versatile mounting. When you pair the right spec with high-quality components like Swiclick’s offerings, you elevate your system’s performance—and your procurement becomes an asset, not a compromise.