How Roller Micro Switches Improve Positioning in Conveyor and Packaging Machines

1. Introduction

In modern conveyor and packaging systems, precise positioning is more than just a technical detail—it’s the difference between smooth operations and costly downtime. One small yet powerful component helps achieve this precision: the Roller Micro Switch. Compact, durable, and highly responsive, it ensures reliable object detection and travel limit control, making it indispensable in automated production lines.

2.How a Roller Micro Switch Works

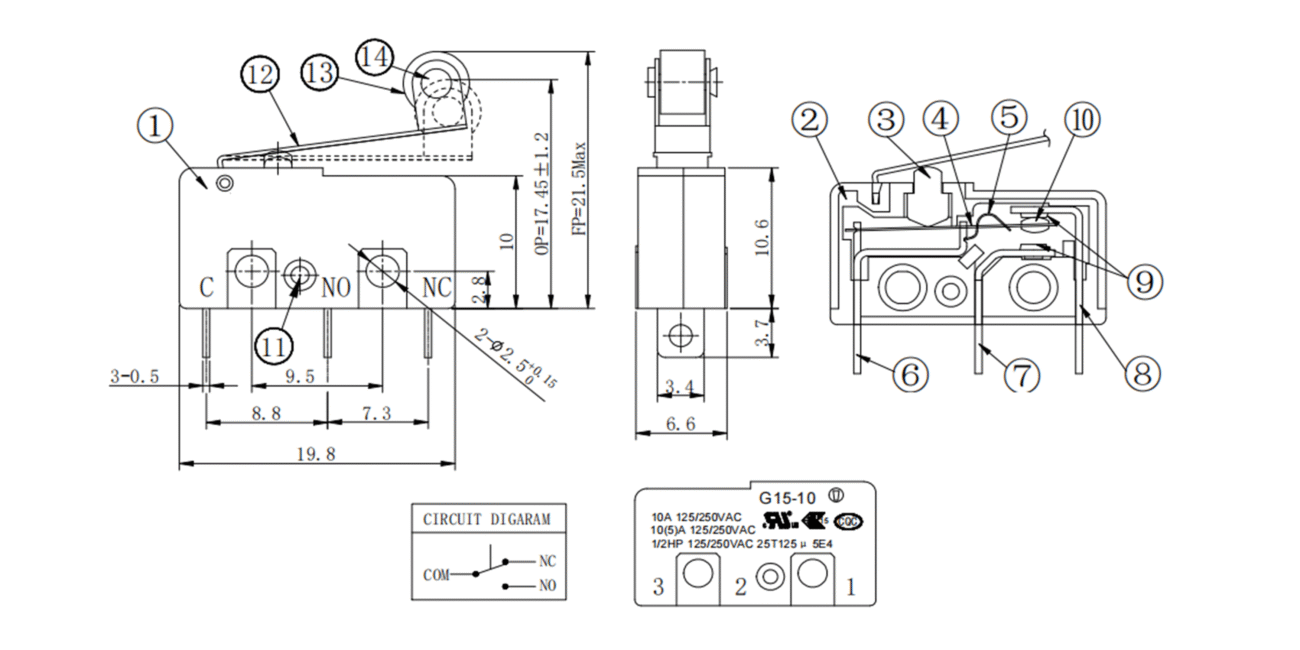

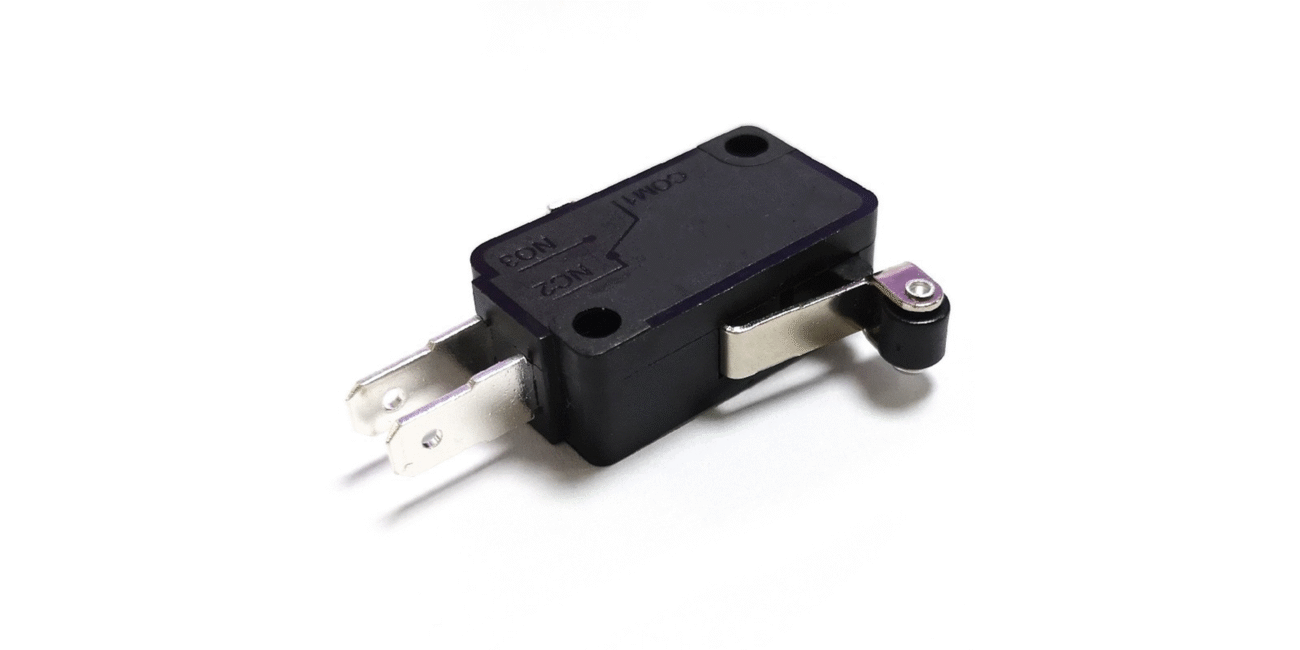

A roller micro switch consists of three key parts: the roller actuator, a lever, and a micro contact mechanism. When an object touches the roller, the lever moves and instantly triggers an electrical signal. Think of it as the “nerve ending” of the machine, transmitting accurate feedback at the exact moment a product reaches its position.

3.Why It’s the Right Choice for Industrial Production

· High precision and repeatability: consistent triggering at the same position every cycle.

· Rugged performance in harsh environments: dust, oil mist, or humidity do not compromise detection.

· Fast response: perfect for high-speed conveyor systems and fast-cycle packaging lines.

· Easy maintenance: straightforward installation and replacement reduce downtime.

4.Applications in Conveyor Systems

1.Presence detection: confirm when products arrive at a workstation.

2.Sorting and merging control: verify that diverters or pushers are in position.

3.Misalignment monitoring: detect belt deviation before failure occurs.

4.Jam detection: identify product buildup and trigger a controlled stop.

5.Applications in Packaging Machines

1.Sealing and heat-seal position verification: ensure sealing arms and jaws reach the correct position.

2.Film tensioning and alignment: maintain accurate pull and positioning of film materials.

3.Carton forming and folding: verify mold and flap positions to prevent damage.

4.Reject and ejection mechanisms: confirm pushers return to position, keeping production smooth.

6.Applications Product Examples

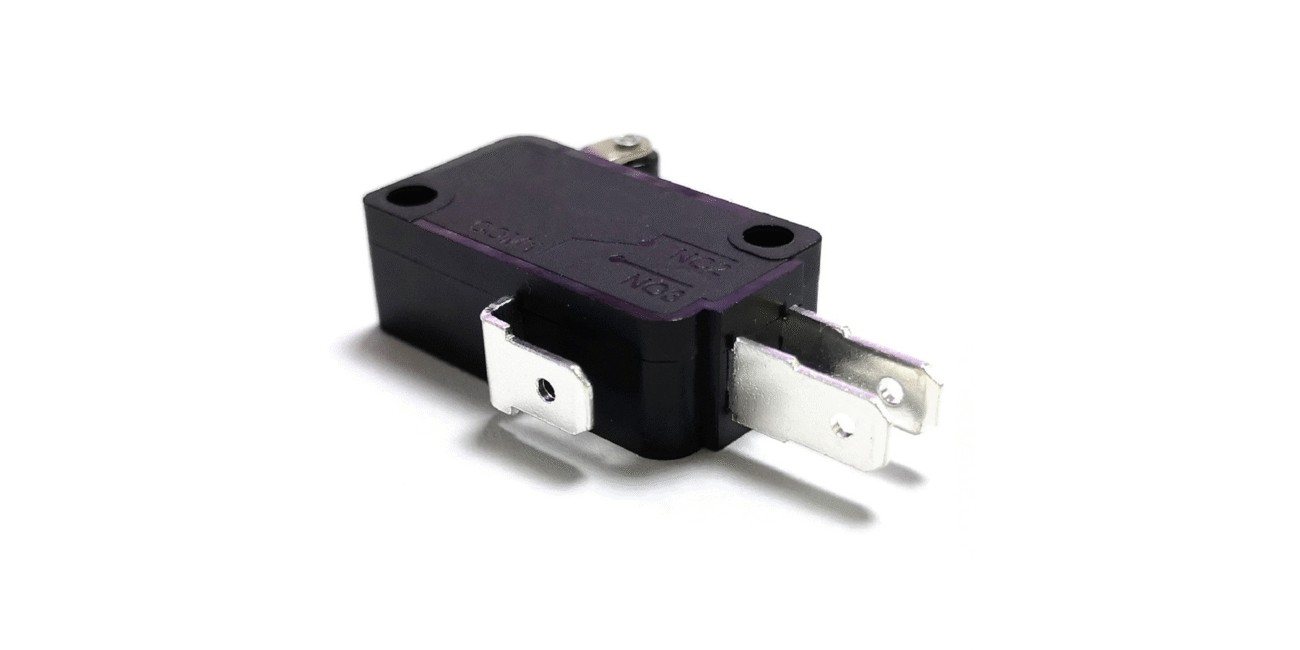

In production lines where precision and reliability are critical, the Roller Micro Switch proves its value through practical applications. For instance, the 25T125-5E4 Micro Switch with Roller Lever is designed for heavy-duty conveyors, providing accurate position detection and long-term durability. Similarly, the 16A 125/250VAC Short Roller Lever Micro Switch is ideal for compact packaging machinery, ensuring smooth operation in limited space. These examples illustrate how roller micro switches enhance efficiency, safety, and product consistency.

7.Key Advantages for Industrial Automation

· Improved efficiency: stable cycle timing with fewer interruptions.

· Better yield: accurate detection reduces defective packaging.

· Less downtime: early detection of jams and over-travel prevents failures.

· Higher safety: position detection supports end-stop and interlock protection.

8.Frequently Asked Questions (FAQ)

Q: How is a roller micro switch different from a standard limit switch?

A: It offers shorter travel, faster response, and compact design—ideal for precise positioning in conveyors and packaging lines.

Q: How can false triggers be avoided in high-speed applications?

A: By selecting the right roller size, lever length, and mounting angle, false trips can be minimized.

Q: Can it work alongside photoelectric sensors?

A: Yes, they complement each other—micro switches provide mechanical certainty, while photo sensors offer non-contact detection.

Q: How do you extend contact life?

A: Use proper load protection, such as RC snubbers or diodes for inductive loads.

9.Conclusion

The Roller Micro Switch may be small, but its role in conveyor and packaging systems is huge. From ensuring accurate positioning to improving safety and reducing downtime, it acts as a reliable guardian of productivity.