Do Snap Action Micro Switches Ensure Precise Office Paper Handling?

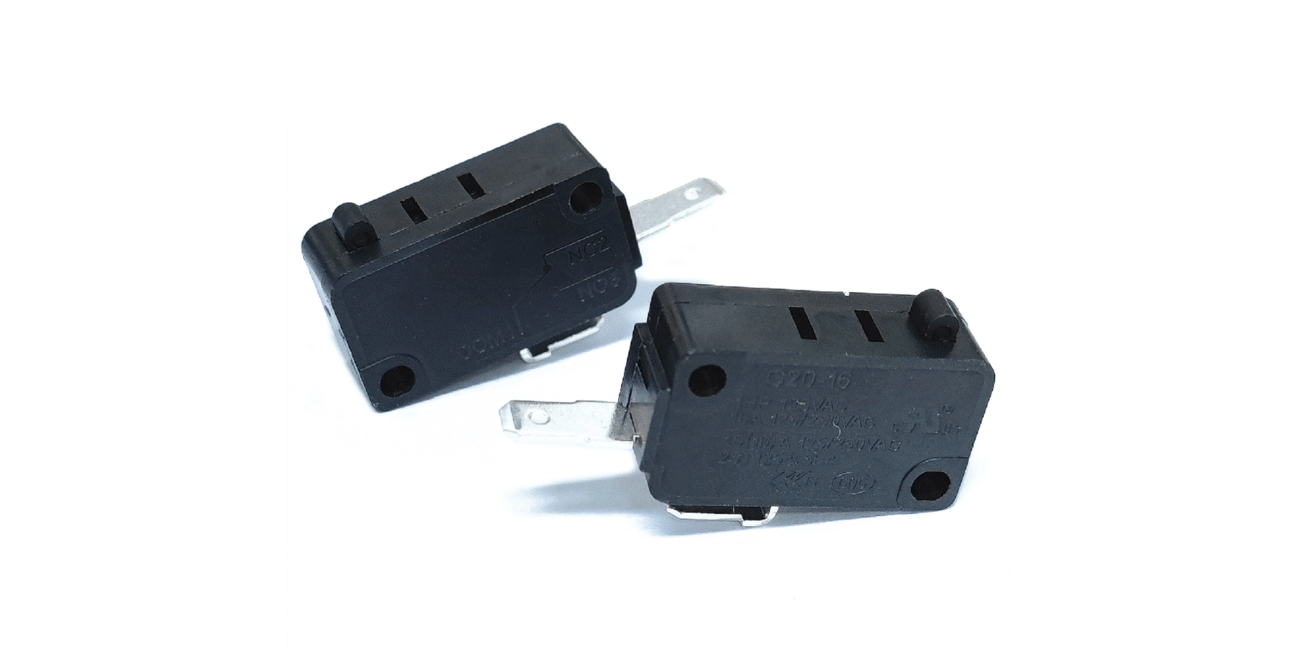

In busy office environments, paper handling systems are everywhere; printers, copiers, fax machines, shredders, scanners. These devices keep documents moving but also rely on accuracy. A single misfeed or jam can slow down an entire workflow. While many people look at these machines and see only plastic casings and trays, inside them are small but important components making sure paper moves smoothly. One of those key parts is the Snap Action Micro Switch.

In the eyes of most it may be tiny, but the speed of responsiveness and dependable functionality provide machine capability to sense the paper, control the motion of the machine and avoid miscommunication. Without switches like these, office equipment would not be nearly as precise or efficient as we know it to be.

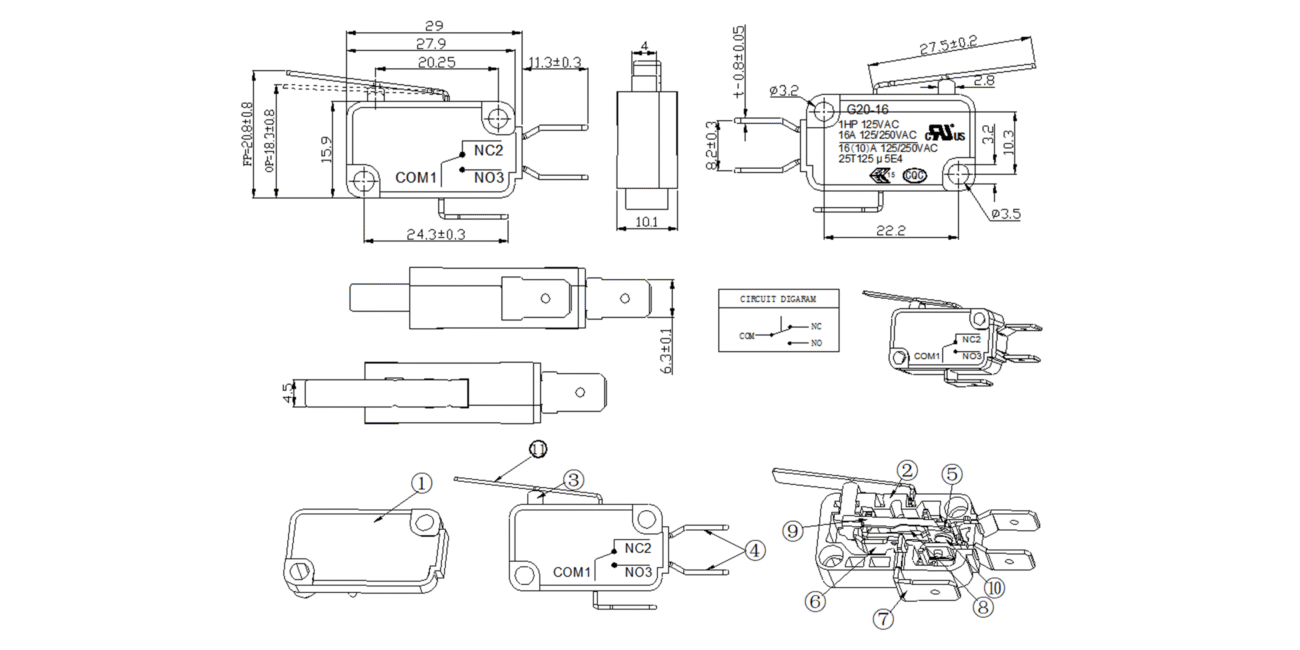

How Snap Action Micro Switches Work?

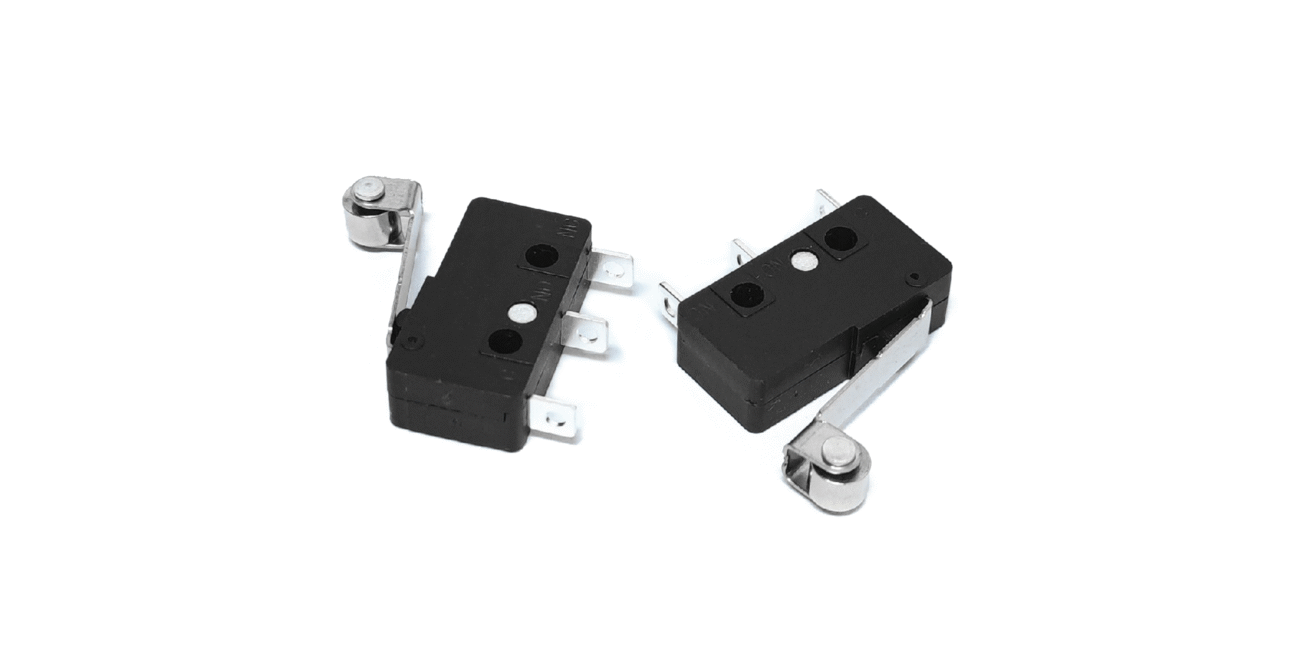

At its simplest, a snap action micro switch is a mechanical switch with a lever or actuator that moves when pressed. Inside, a spring-loaded mechanism snaps from one position to another once a certain force is applied. That quick “snap” is what makes it different from a regular switch.

Instead of slowly sliding from off to on, it instantly flips the electrical state with minimal travel. That fast action creates several benefits:

- Precise detection – It changes state at almost the exact same point every time.

- Fast response – The spring mechanism ensures quick switching, no delay.

- Reliability – Fewer chances of half-contacts or weak signals.

For paper handling, this is important because machines need to know right away if a sheet has reached a sensor, or if a tray is empty, or if something has gone wrong.

Even a fraction of a second delay could cause misalignment or paper jam. The snap action design keeps timing consistent.

Why Snap Action Micro Switches are an ideal choice for Office Paper Handling

Office machines run constantly and often in heavy cycles. A copier in a corporate office may handle thousands of sheets in a single day. So, the switches inside need to be more than just functional, they must be durable, accurate, and long-lasting.

Snap action micro switches meet these demands because:

- They operate reliably for millions of cycles without losing accuracy.

- Their compact size fits easily into tight paper pathways.

- The crisp actuation reassures designers that detection happens exactly where intended.

Compare this to other sensing methods like optical sensors—those can get dirty with dust or toner particles, reducing accuracy. Mechanical snap switches, on the other hand, still keep working in dusty, busy environments. That’s why they are such a practical choice for printers, copiers, and shredders.

Applications of Snap Action Micro Switches in Office Paper Handling

The demand for error-free paper flow means snap action micro switches appear in several points across office machines. Some common applications include:

- Paper Presence Detection – Switches confirm when a sheet enters the feed system, helping rollers pull paper at the right time. For example, a Micro Switch with Roller Lever Arm (3-Pin, 5A 125/250VAC) is often used in such detection points, as its roller lever design allows smooth and accurate paper sensing.

- Tray Empty/Full Detection – Micro switches mounted at the bottom of paper trays detect when the supply runs out or when a tray is inserted correctly. Compact designs like the 2-Pin Terminals Normally Open Micro Switch are commonly used here, ensuring dependable performance with a simple connection.

- Jam Detection – When paper gets stuck, the switch can trigger a warning to stop further feeding before damage occurs. Devices such as the Lever Rice Cooker Micro Electric Switch, though widely applied in home appliances, are also well-suited for this function in office equipment thanks to their fast actuation and strong durability.

- Cover Interlocks – Many copiers or printers won’t operate if a cover is open. Snap action switches secure this safety feature by immediately cutting off the circuit when covers are lifted.

- Shredders and Finishing Units – Switches detect paper entry in shredders or staplers inside copiers to ensure safe and precise operation. Roller-lever types or normally open versions are often chosen for these areas depending on the design.

Every one of these functions depends on fast switching and repeatable accuracy, making the snap action micro switch a silent workhorse behind office productivity.

Advantages of Snap Action Micro Switches in Paper Handling Systems

Snap action micro switches bring several advantages beyond just switching. These benefits are the reason they remain common in office equipment designs even with newer sensing technologies available.

Safety – In shredders or copiers, interlock switches prevent accidents by disabling operation when covers are open.

Accuracy and Consistency – Each actuation occurs at almost the same force and position. This predictability minimizes feeding errors.

Durability – Quality snap action switches are tested for millions of actuations, which is ideal for machines that run on a daily basis.

Compactness – Small housings let designers incorporate into narrow paper paths.

Cost Value – Snap switches are less expensive compared to complex electronic sensors, and can be reliably counted on for many years.

Versatility – Available with different operating forces, terminal types and lever shapes, so engineers can specifically adapt to their paper handling designs.

Frequently Asked Questions (FAQ)

Q1. How long does a Snap Action Micro Switch last in office equipment?

A1. Most are rated for millions of cycles. In a typical office printer or copier, a well-made switch can easily last several years of heavy use.

Q2. Are they better than optical sensors for paper detection?

A2. Not always better, but more dependable in dusty or toner-filled environments. Optical sensors can get blocked, while mechanical switches keep working.

Q3. Can these switches be customized for different machines?

A3. Yes, manufacturers offer a wide range; different sizes, lever lengths, and terminal options. That flexibility helps in designing specialized paper paths.

Q4. Do snap action micro switches require maintenance?

A4. Normally no. They are sealed or semi-sealed, so they operate maintenance-free. Replacement is only needed if one wears out after long years of use.

Conclusion

Office paper handling may look simple from outside, but inside machines there are dozens of small parts working in sync. TheSnap Action Micro Switchis one of those unsung heroes.

Its quickness of action, reliability, precision, and durability help keep the paper moving smoothly through printers, photocopiers, shredders, and other applications.

As long as offices continue to demand faster and more reliable machines, engineers will continue to build with this proven technology to manage the details.