Can Micro SMD Switches Achieve Extreme Design in 3C Miniaturization?

1. Introduction

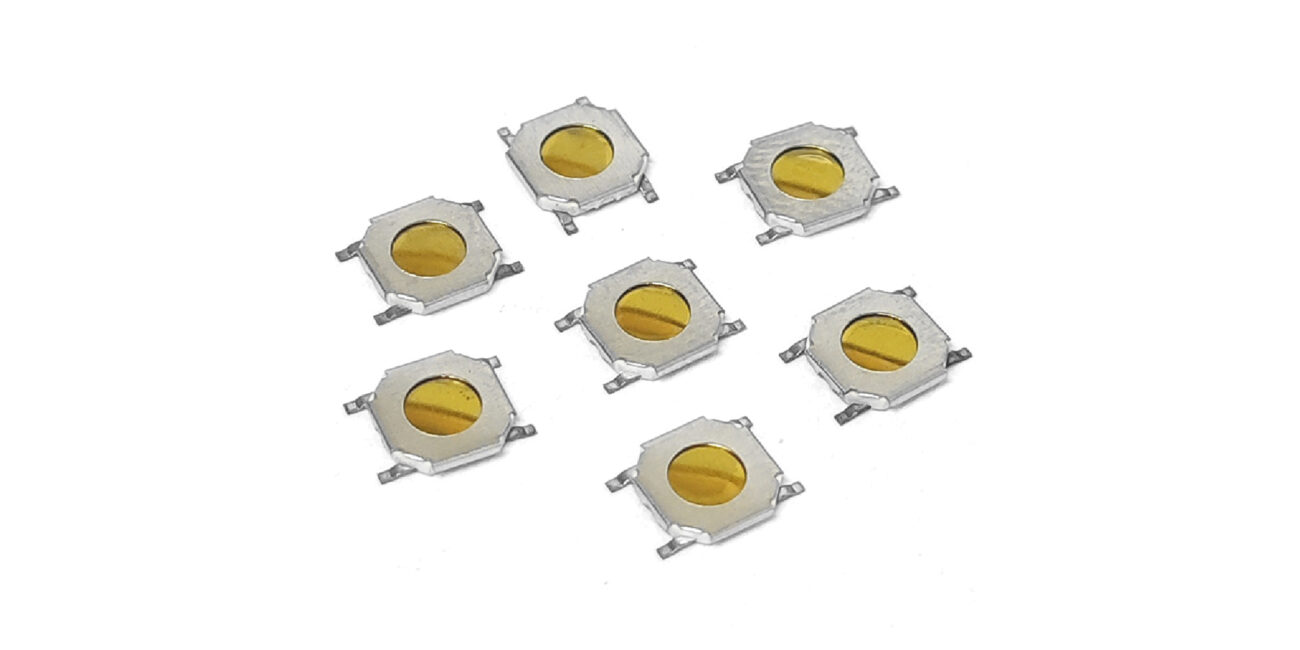

Modern 3C devices—computers, communication tools, and consumer electronics—are designed ever thinner, more lightweight, and more compact. As PCB real estate shrinks and enclosure thickness approaches millimetres, designers face tight constraints on internal components. Enter the Micro SMD Switch, a precision-engineered tact switch enabling dense, ultra-low-profile layouts. Swiclick offers a comprehensive range of such ultra-miniature tact switch designs suited for these stringent requirements.

2. Definition and Construction of Micro SMD Switch

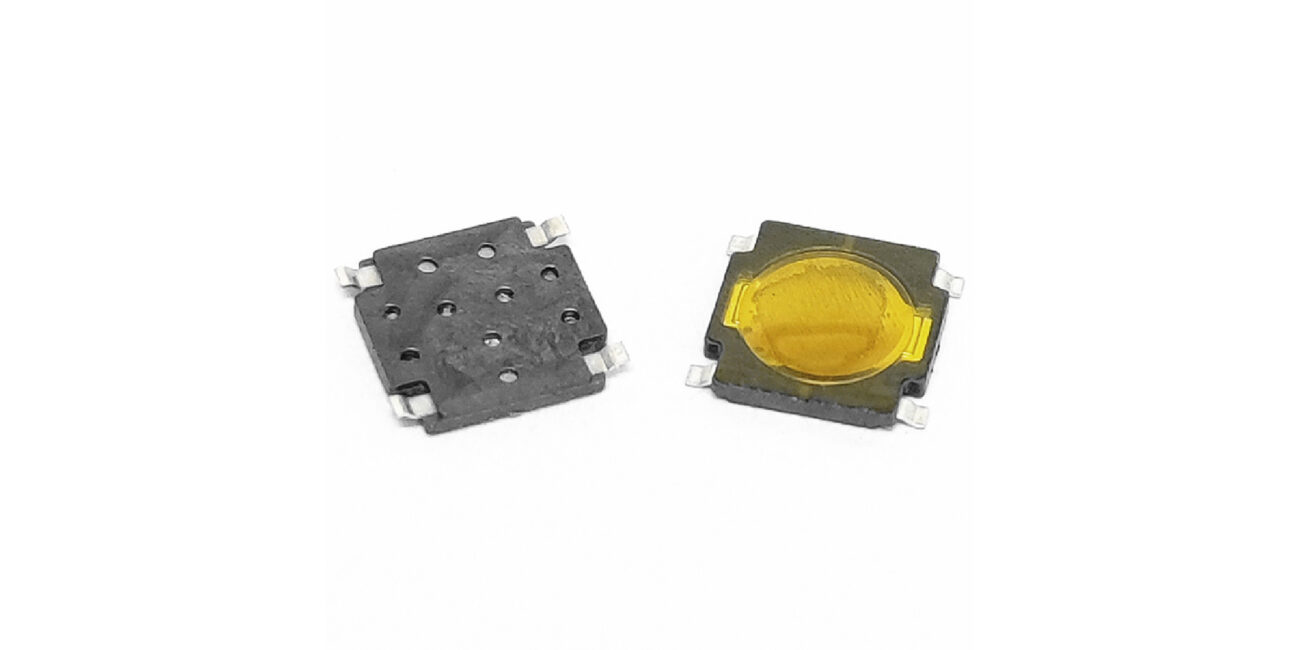

A Micro SMD Switch refers to a surface-mount tactile switch whose overall body dimensions typically do not exceed 6 mm. These components are engineered for minimal profile (often < 1 mm actuator travel or < 2 mm height), mechanical snap-action tactile feedback, and compatibility with high-speed, high-precision SMT processes. Depending on design, internal construction may use a metal dome or a rubber-sealed actuator to balance between tactile sharpness and environmental sealing.

3. Supporting Ultra-Thin and High-Density Layouts

To illustrate real-world implementation, consider the Mini Surface Mount 3×6×2.5 mm Tact Switch and Microminiature 5.2 mm Mouse Tact Switch from Swiclick’s product line. These switches occupy minimal board space—only 3 × 6 mm and approximately 5.2 mm footprints respectively—while maintaining a low profile with thin actuator assemblies. Their dimensions allow designers to densely populate PCBs within ultra-slim enclosures such as compact mice, handheld remote controls, and wearables.

These real examples demonstrate that tactile reliability and lifetime durability can be maintained even when overall thickness and board area are significantly reduced. When compared against typical benchmark switches (such as those with dimensions around 4–5 mm and operational life up to hundreds of thousands of cycles), the Swiclick models align closely or exceed these performance levels while fitting into tighter spaces. This makes them ideal for designers pushing the envelope in 3C miniaturization.

4. Performance and Reliability in Tactility

Procurement-grade switches offer defined actuation force ranges (e.g. 100 gf ± 30 gf through 250 gf ± 50 gf), precise snap feedback, and electrical ratings suitable for signal-level switching (typically 50 mA @ 12 VDC). Mechanical and electrical life expectancy often exceed 100,000 cycles, with contact resistance typically under 100 mΩ. These specifications provide procurement engineers with quantifiable criteria for supplier evaluation.

Swiclick’s Micro SMD Switches—like the Miniature 4×4 mm Dome Tact Switch and 4 Pin SMD Brass Push Button—offer stable actuation forces from 100 gf to 260 gf, with crisp tactile feedback from precision dome structures. These switches typically support 50 mA @ 12 VDC signal-level loads and exceed 100,000 cycles in mechanical life, with contact resistance kept under 100 mΩ.

5. Environmental Protection and Durability

Swiclick’s Miniature IP67 SMD Rubber Tact Switch—such as the 3×6 mm J-Bend model—features a sealed rubber actuator design that complies with IP67 standards for dust and water resistance. This construction effectively isolates internal contacts from moisture and contaminants, ensuring stable tactile response and electrical performance even under prolonged outdoor or high-humidity conditions.

For ruggedized consumer electronics, handheld devices, or industrial control panels, this type of sealed Micro SMD Switch provides reliable long-term operation and reduces the risk of failure due to environmental exposure.

6. Mounting Styles and PCB Integration

Micro SMD switches employ varied pin and actuator configurations:

– Straight SMT J‑bend pins provide mechanical robustness in ultra-miniature designs.

– Side-actuated (side push or photo-side) variants support edge-triggering, useful when device bezels or frames interface directly with the switch.

All forms are compatible with high-speed machine placement and standard reflow profiles, minimizing footprint while maintaining assembly reliability.

7. Typical Applications and Industry Relevance

These compact switches are widely used in wearables (e.g. smart bands), ultra-thin remote controls, mobile mice, and medical handheld devices. Designers choose micro-scale tact switches for their compact size, reliable lifecycle, and predictable tactile response—even under harsh environmental conditions.

8. Why Procurement Teams Choose the Right Micro SMD Switch Matters

When it comes to 3C product design, selecting the right Micro SMD Switch isn’t just about size—it’s about long-term performance, durability, and supplier reliability. From low-profile mounting to high-tactile accuracy, these switches play a foundational role in product quality and user satisfaction.

Swiclick offers a comprehensive lineup of Micro SMD Switch options through its Tact Switch Series, featuring variations in actuation force, sealing level (including IP67), footprint, and mounting format. Whether you need a Micro SMD Switch for ultra-slim wearable devices, rugged outdoor controls, or densely packed PCBs, Swiclick’s modular product portfolio allows engineers and sourcing teams to match precise technical requirements with scalable procurement.

Choosing a proven, specification-backed switch supplier isn’t just a design decision—it’s a strategic investment in manufacturing consistency.

9. Specifying Considerations and Procurement Strategy

• Verify physical dimensions (body, actuator travel, pin pitch) especially for applications with internal clearances under 1 mm.

• Confirm mechanical life cycle ratings (≥ 100k cycles preferred) and contact resistance targets (≤ 50–100 mΩ).

• Review soldering profiles and reflow recommendations in datasheets to ensure compatibility with your PCB assembly process.

• Sample testing is essential: request parts early in design cycle to validate actuation feel, force consistency, and assembly yield before bulk procurement.

10. Conclusion

In conclusion, Micro SMD Switches offer unmatched potential for enabling extreme miniaturization in 3C product designs—delivering compact footprint, reliable tactile feedback, long lifespans, and selectable environmental sealing.